Labscale Flat Sheet Membrane Casting Machine

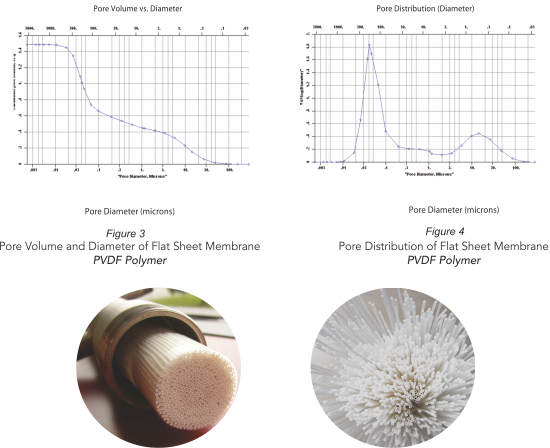

The Pore Structures of the membranes made in the PMI membrane making machines were determined by various pore structure characterization techniques. The Pore structures of hydrophobic

Flat sheet membranes were measured by water intrusion porosimetry.The Pore volume at 20 micron is probably due to pore diameter. Pores have diameter from about, 50 to 0.01 micron.

Principle

-

Solutions for making membrane are throughly mixed at desired temperature and pressure. The Chemicals are shaped in to flat sheets or hollow fibers and allowed to coagulate at the desired temperature.

Basic Layout

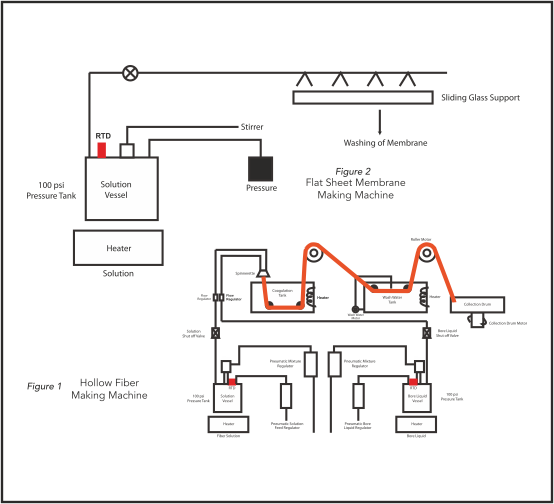

Layput of the hollow fiber making machine is showing figure 1. One hundred PSI pressure tanks hold chemical at the desired temperature and pressure. the chemicals are constantly

stirred and pumped to the spinnerette. flow ragulators control the flow rates of the chemicals. The hollow fibers coming out of the spinnerette pass through a temperature controller coagulation

tank and are washed. Figure 2 shows the layout of the flat sheet membrane making machine.

Pore Structure of Membrane

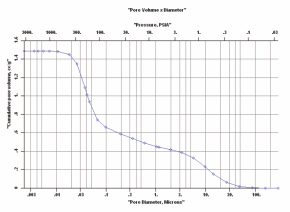

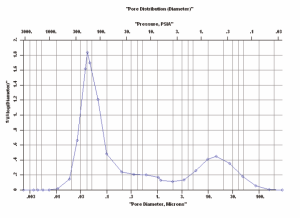

The Pore Structures of the membranes made in the PMI membrane making machine were determined by various pore structure characterization techniques. The pore structures of hydrophobic

flat sheet membranes were measured by water intrusion porosimetry. Figure 4 shows variation of hydrophobic pore volume with pore diameter. Pores have diameter from about, 50 to 0.011 microns.

The pore distribution in figure 5 shows the pore making maximum contribution to the pore volume are about -0.04 microns in diameter. The pore volume at 20 microns Is probably due to pure mouths. The pore structures of the membranes made in the PMI membrane making machines were determined by the various pore structure characterization techniques. The pore structures of hydrophobic flat sheet membranes were measured by water intrusion porosimetry.